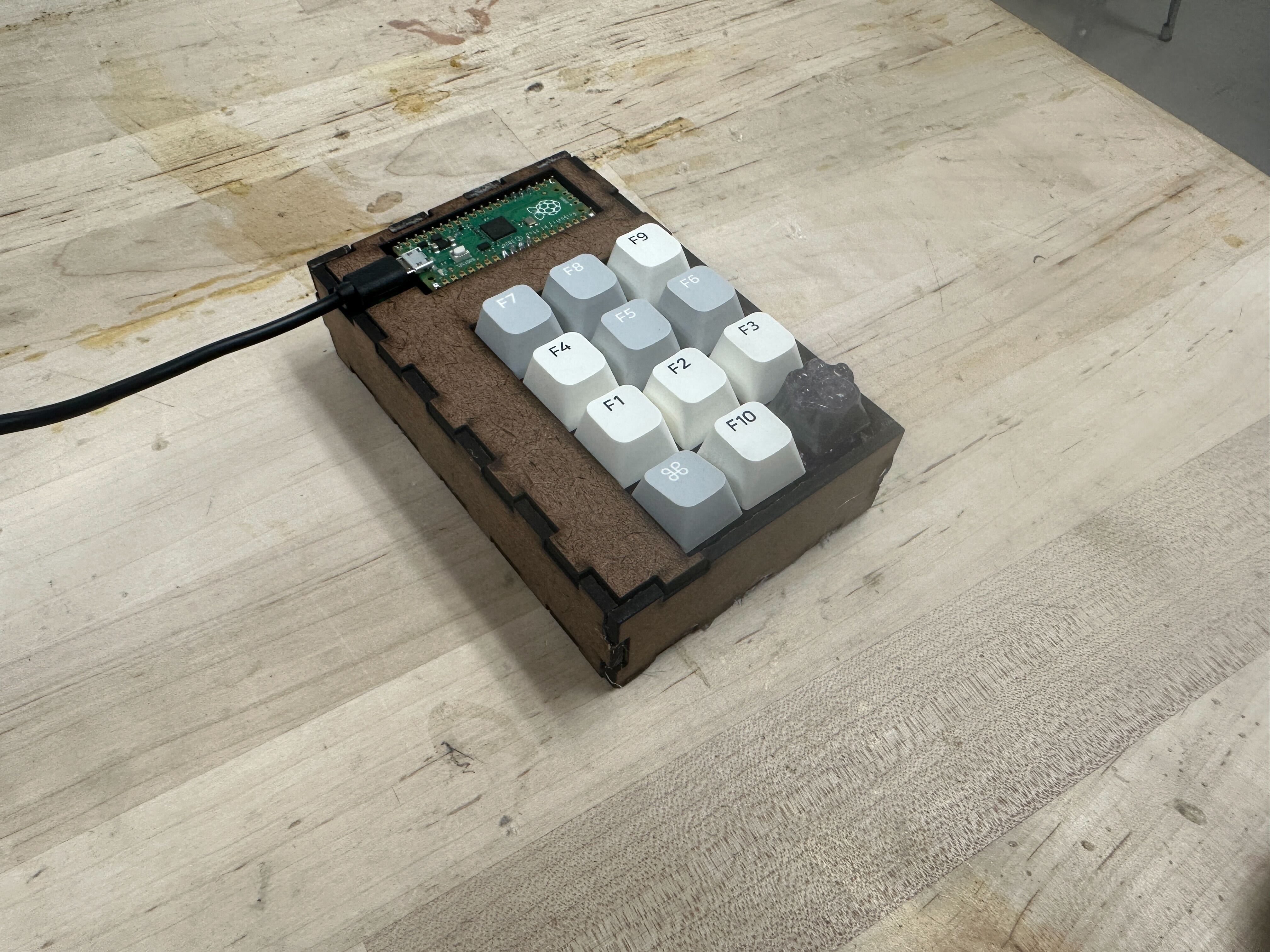

Programable Macro Pad Workshop

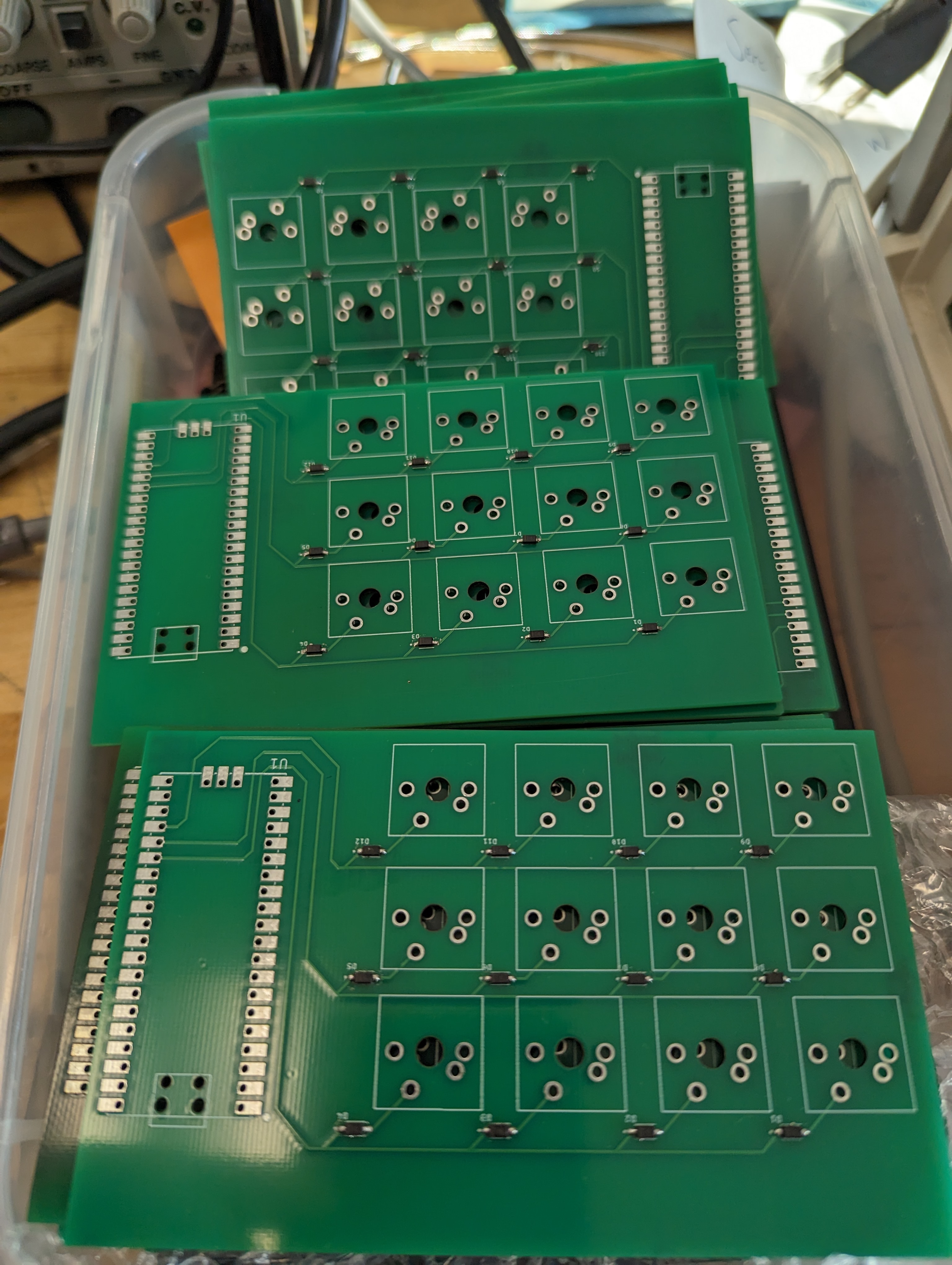

Throughout this multi-part workshop, students learned various skills including PCB design, circuit theory, microcontroller programming, keyboard matrix theory, advanced soldering, molding and casting, 3D printing, and more. The series synthesized these skills into one extended project, a programable macro pad.

Students were highly engaged both inside and outside the workshops, returning to the spaces throughout the week to continue developing and customizing their macro pads using the 3D printers, CNC routers, and a variety of lower-resolution tools.

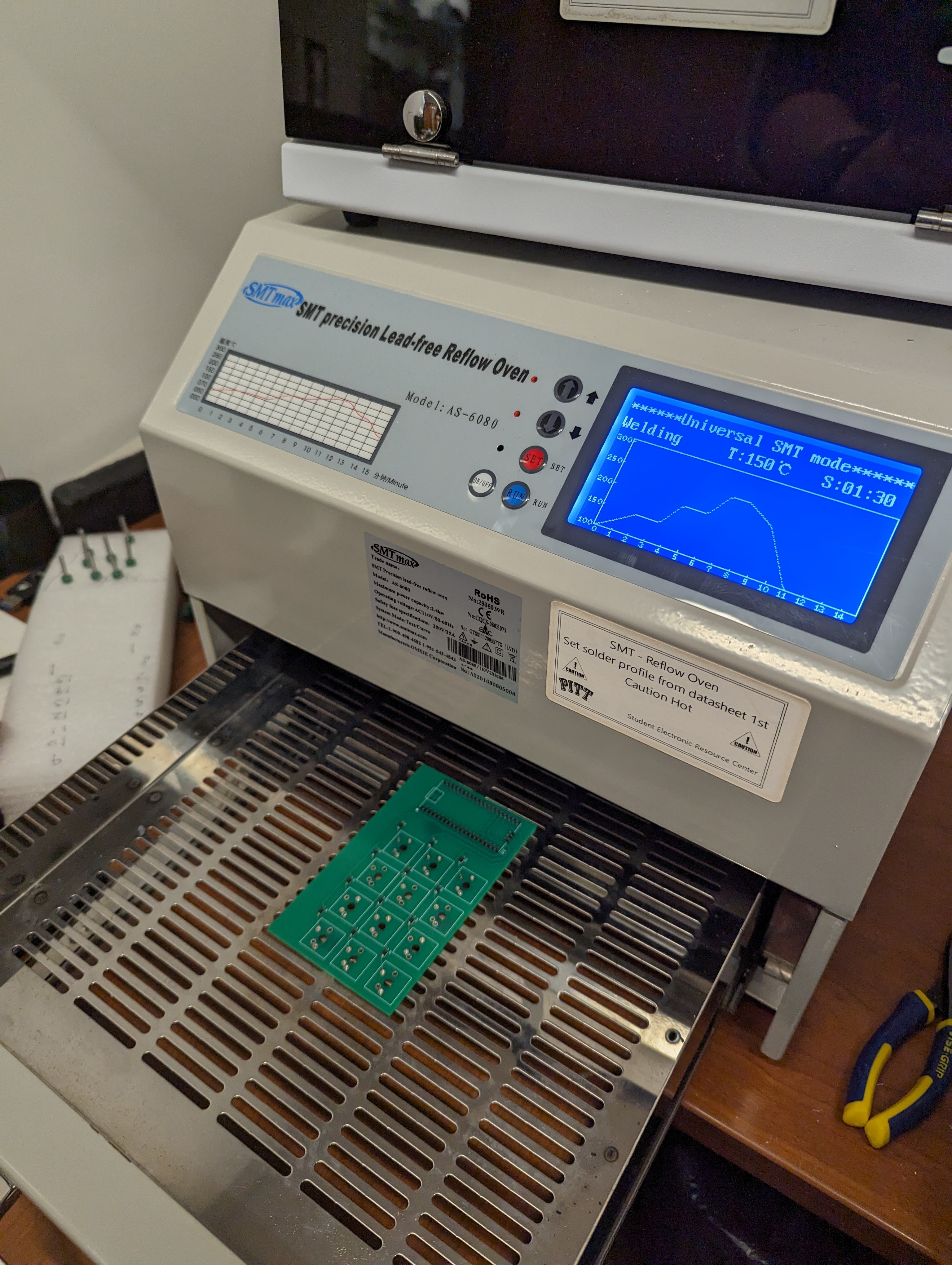

I led the development and execution of this workshop as a member of the Pitt Makerspace Program Committee—the student group responsible for bi-weekly educational programs open to the entire University community. Split into three parts, the program covered PCB Design and Manufacturing, Resin Casting and Silicone Molding, and Advanced Soldering. My responsibilities included generating curriculum for each session, adapting open source projects into the final electronic design, sourcing necessary components, physically preparing material kits, managing a team of peers, and presenting at the final workshop sessions.

Throughout the project I learned how to use a soldering reflow oven to solder surface mount devices, EAGLE and KiCAD for PCB design, the CircuitPython environment, as well as gaining an intimate understanding of how a keyboard operates.

- © Drew Deffenbaugh

- Thanks to HTML5 UP